7 State-of-the-Art production facilities

plants and facilities

Overview

We believe in to provide complete end to end solutions to our customers, this is why we are offering complete gearboxes assemblies along with a highly automated gear cutting facility.

Over 50 years of experience Grudiva has created world class capacities and capabilities that has allowed our industrial Group to meet the development and delivery timeline with quality products.

We have installed world and State of Art Manufacturing facilities for various processes which help us to provide complete solutions to our customers.

TYPE OF PROCESS : FORGING

Forging Plant in Aurangabad, India

TYPE OF PROCESS : GEAR CUTTING CNC

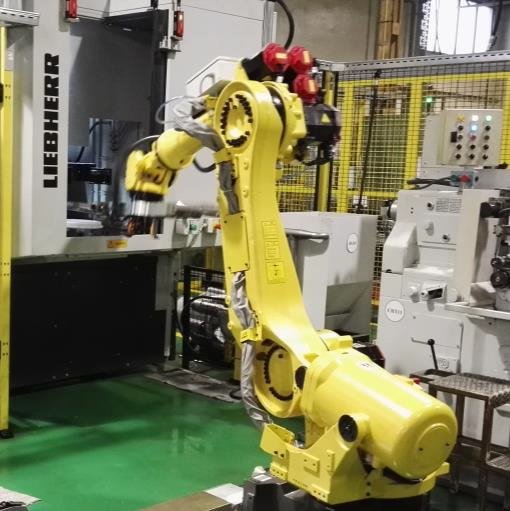

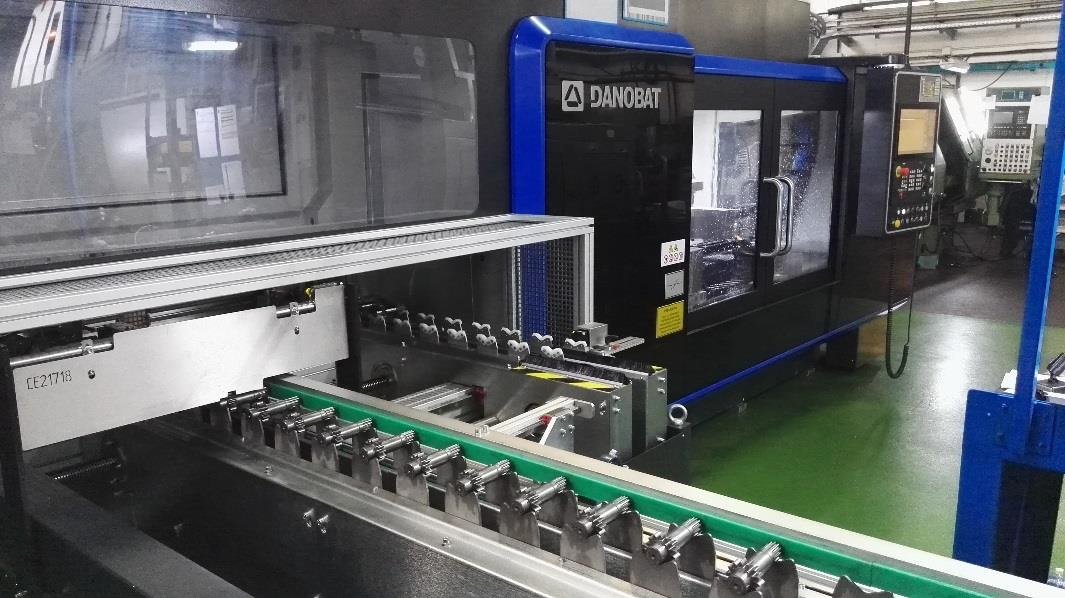

Automated Robotic Lines

CNC Hobbing machines

Shaving Machines

CNC Shaping machines

Broaching machines

CNC Sharpening machines

TTI Gear Profiles Tester

Conventional measuring instruments

Gear Cutting

Gear Cutting

TYPE OF PROCESS : HEAT TREATMENT

Fully Automated Manless

Operating Sealed

Quenching Furnace (start production in Jan_14)

Continuous Multi Chambered Furnace

Bell Furnaces

Shot Blasting machines

Metallurgical Lab

Heat treatment

TYPE OF PROCESS : POST HEAT TREATMENT

ID and OD Grinding

Hard Turning

Component washing machine

Inspection Stations

Auto shaft Straighteningmachines

TYPE OF PROCESS : ASSEMBLY COMPONENTS

CNC Vertical Machining Centers

CNC Horizontal Machining Centers

CNC Lathes

Broaching machines

Hard Turning

ID and OD Grinding machines

Our Clients

CNC Balancing Machines

Automated Tool Dispenser

TYPE OF PROCESS : INSPECTION

CMM

Profile Tester

Crack Detection

Contracer

Cleaness lab

TTI Klingelnberg tester

Calibration equipment

Another conventional measurement equipment

TYPE OF PROCESS : ASSEMBLY & PAINTING

Automated Assembly Lines

Leakage test

Run Off test

Kardex chain supply system

Complete Automatic Washing Line